With the rapid development of China's economic construction and the increasing scale of industrial production, explosion-proof issues have become more important. Explosion proof electrical products with diverse functions and varieties are widely used in various industries such as petroleum, chemical, and coal. Explosion proof electrical appliances must strictly comply with relevant national laws, regulations, and standards in their selection, installation, use, and maintenance. Shenzhen Zhongnuo Testing Technology Co., Ltd. has rich experience in product design and testing in the field of explosion-proof. The following is a brief introduction to the installation, inspection, maintenance, and usage precautions of explosion-proof electrical equipment.

1.1 Distribution requirements for electrical equipment

1.1.1 The power supply for entering explosive hazardous areas should adopt a 3-phase 5-wire system; If it is a 3-phase 4-wire system, it should be converted to a 3-phase 5-wire system first in a safe place;

1.1.2 The grounding resistance of the protective ground wire should meet the relevant standard requirements (≤ 10 Ω);

1.1.3 The impact of lightning on electrical equipment should be considered;

1.1.4 If the automatic power-off of electrical equipment may cause greater danger than the risk of ignition, an alarm device should be used instead of the automatic power-off device. However, the alarm of the alarm device should be obvious in order to take remedial measures in a timely manner;

1.1.5 In order to prevent sudden power outages and ensure power supply reliability, explosive hazardous areas should be powered by dual power sources and equipped with automatic switching devices;

1.1.6 In order to handle emergency situations, one or more measures should be taken at appropriate locations or locations in hazardous areas to power off electrical equipment in hazardous areas. To prevent additional hazards, electrical equipment that must operate continuously should not be included in emergency power-off circuits, but should be installed on separate circuits;

1.1.7 If necessary, a leakage protector can be installed. When the leakage current exceeds the standard, the power supply should be quickly cut off.

1.2 When selecting explosion-proof products, attention should be paid to the main factors such as explosive gas environment, protection level, and anti-corrosion level requirements to ensure that the selected explosion-proof products meet the usage requirements. If there is any improvement or change, it is necessary to replace the corresponding level and group of explosion-proof products in a timely manner to ensure environmental safety. The specific selection principles are as follows:

1.2.1 Principle of safety and reliability: The category, level, and group of equipment should be suitable for the environment in which it is used;

1.2.2 Economic principle: Equipment selection does not need to be highly selective. For products of the same level, factors such as price, lifespan, reliability, operating costs, energy consumption, and availability of spare parts should be considered;

1.2.3 Environmental adaptability principle: Consider environmental temperature, humidity, and atmospheric pressure; Shell protection level and corrosion resistance performance, etc;

1.2.4 Maintainability principle: Under the same conditions, products with simple structure and light weight should be selected; When necessary, system operation requirements should also be considered, such as prioritizing the selection of intrinsically safe products for continuous automation systems;

1.2.5 Additional requirements:

a) Only Ex ia products are selected for Zone 0 locations, and double explosion-proof requirements may be considered if necessary;

b) Equipment and high-voltage equipment that often form ignition sources inside the shell should not be used in Zone 1 locations;

c) Equipment with unstable temperature rise should not be used in Zone 2 locations. If necessary, Ex d/Ex p equipment should be selected.

1.3 Electrical equipment should be installed in accordance with the prescribed technical documents. The power supply of electrical equipment should be equipped with appropriate protective devices to avoid harmful effects caused by overload, short circuit, open circuit or ground fault. For example, the increased safety squirrel cage motor should be equipped with an inverse time limit protection device. Short circuit and ground fault protection devices should be able to prevent automatic reclosing under fault conditions. Pay attention to ensuring that the replacement items, such as replacing light bulbs, must match the type and rated value of the usage requirements. The equipment installation is completed, and the initialization check of the equipment and installation should be carried out in accordance with IEC60079-17.

1.4 Explosion proof electrical equipment should be installed by construction personnel with professional knowledge. The installation quality should meet national standards such as GB50257 and GB3836.15. When necessary, professional explosion-proof organizations can be entrusted to carry out engineering supervision or on-site guidance for engineering installation, to ensure that the engineering project meets the overall explosion-proof standards.

1.5 Proper installation of electrical equipment, for existing installations or expansion of existing installations, attention should be paid to the following points:

1.5.1 Site classification documents;

1.5.2 Equipment installation and connection instructions;

1.5.3 Explanatory documents for intrinsic safety systems;

1.5.4 Declaration of qualified personnel from the manufacturing plant.

During installation or maintenance, the previous power supply must be cut off, and the operation must be carried out according to the warning requirements in the product manual, such as "Do not open the cover with electricity" or "Power off for XX minutes before opening the cover". After cooling down, open the cover to avoid accidental injuries such as electric shock and burns.

If subjected to vibration, special attention should be paid to the tightness of equipment bolts and cable entry devices. When cleaning non-metallic electrical equipment, attention should be paid to avoiding the generation of static electricity.

1.7 The installation and use of explosion-proof electrical equipment should prevent adverse effects of external factors (such as chemical, mechanical, thermal, electrical, and moisture) on explosion-proof performance, and measures should be taken to prevent foreign objects from vertically falling into the ventilation openings of vertically installed motors.

1.7.1 moisture-proof and waterproof measures:

For outdoor places, explosion-proof electrical appliances should be placed under rain shelters as much as possible to avoid direct rain and direct sunlight, and products with higher protection levels should be selected as much as possible. Seal the entrance of electrical circuits. And take measures to prevent water accumulation near explosion-proof electrical appliances. Apply waterproof agent to the threaded connection of the installed wiring pipeline;

1.7.2 Anti corrosion measures:

According to the presence of corrosive gases, liquids, and vapors in the environment, in addition to selecting corrosion-resistant explosion-proof electrical appliances, anti-corrosion treatment should also be carried out on wiring pipelines.

1.7.3 Heat prevention measures:

Try to keep explosion-proof appliances away from heat sources and choose explosion-proof appliances with higher temperature levels as much as possible.

1.7.4 Seismic measures:

Try to use copper core insulated flexible wires or copper core multi stranded cables. When wiring with metal pipes, flexible connection pipes can be installed at the connection between explosion-proof electrical appliances and electrical circuits as needed. Spring washers and double nuts are used to prevent loosening of bolt fasteners that are susceptible to vibration.

1.8 Requirements for wiring and grounding:

1.8.1 The connectors and grounding terminals should have sufficient mechanical strength and ensure reliable connection. Although affected by temperature changes, vibrations, etc., poor contact should not occur. If aluminum core cables are used, transition joints should be used to avoid electrolytic corrosion.

1.8.2 The metal casing of electrical equipment and the junction box of armored cables must be equipped with external grounding bolts and marked with grounding symbols. Portable and mobile devices do not have external grounding bolts, but cables with grounding cores must be used.

1.8.3 Electrical equipment junction boxes must be equipped with dedicated internal grounding bolts and marked with grounding symbols. When using the direct introduction method, it is located inside the main chamber. But for electrical equipment on electric locomotives, internal and external grounding bolts are not required.

1.8.4 Pipelines that transport combustible gases or liquids should not be used as grounding wires. If the equipment is installed on a grounded metal frame or installed using a well grounded conduit wiring method, it can be considered as having external grounding. Electrical equipment should be equipped with grounding connectors next to the circuit connectors in the wiring cavity.

1.8.5 The connection between electrical equipment and grounding wire should use multi stranded flexible wire, and the minimum cross-sectional area of the copper wire should not be less than 4mm2. Protective pipes should be installed in areas prone to mechanical damage.

The diameter of the internal grounding bolt in 1.8.6 should comply with the following regulations:

a) When the cross-sectional area of the conductive core wire is not greater than 35mm2, it should be the same diameter as the connecting bolt;

b) When the cross-sectional area of the conductive core wire is greater than 35mm2, the diameter of the bolt connecting the conductive core wire should not be less than half of the cross-sectional area, but at least equal to the diameter of the bolt connecting the 35mm2 conductive core wire.

1.8.7 The specifications of external grounding bolts should comply with the following regulations:

a) Equipment with a power of 250W-5kw, not less than M6;

b) Equipment with a power not exceeding 250W and a current not exceeding 5A shall not be less than M5;

c) For intrinsically safe equipment and instruments, the external grounding bolt can press the grounding core wire tightly;

d) The grounding bolt should be made of stainless steel material or undergo electroplating rust prevention treatment.

1.9 When wires or cables are introduced or removed from explosion-proof products, the original rubber sealing rings and retaining rings must not be discarded and directly connected with copper pipes or flexible pipes. They must be fully compressed and sealed. The outer diameter of wires and cables should match the inner diameter of the sealing ring (users should ensure that the minimum size of the selected cable, including tolerances, is greater than or equal to the value required by the cable sealing ring), and the rubber sealing ring material should comply with the aging test in relevant type tests, and its shape should be suitable for the installation of the cable used. Redundant cable entries should be sealed with blind gaskets or metal plugs. Multiple cables are not allowed to enter the same entry device at the same time. Cables used in hazardous areas must not have intermediate joints.

The explosion-proof surface of a 1.10 explosion-proof product is the basic guarantee of its explosion-proof performance. Pay attention to strict protection, avoid scratches, scratches, and sand holes. The explosion-proof surface of each product should be coated with rust proof oil before leaving the factory, and painting is strictly prohibited to prevent oxidation and rusting of the explosion-proof surface. Pads can only be used when permitted by document regulations. The joint surface shall not be treated with substances that have hardened during use. If rust proof oil is found to be dry or reduced, it should be replenished in a timely manner to ensure the normal operation of explosion-proof. The fastening bolts of the explosion-proof joint surface shall not be replaced arbitrarily, and the spring pads shall be complete.

When installing junction boxes for external wire or cable connections, attention should be paid to ensuring that the electrical clearance and creepage distance meet the corresponding standard requirements. (Should meet the relevant requirements in GB3836.3-2010 and GB/T 14048.1-2000)

1.12 All fasteners are equipped with spring washers as anti loosening measures and cannot be discarded. They must be fully compressed each time and flattened with spring washers. Only tools are allowed to loosen or remove fasteners that are necessary to ensure explosion-proof type or to prevent contact with exposed live parts.

The fitting clearance of explosion-proof products with sealing, cylindrical, and threaded explosion-proof structures is usually between 10-20 μ Between m, the average surface roughness of the explosion-proof joint surface shall not exceed 6.3 μ m. Very precise, therefore, when opening or separating, attention should be paid to maintaining balance, separating with light force, and strictly prohibiting pulling or pulling to avoid damaging the explosion-proof performance.

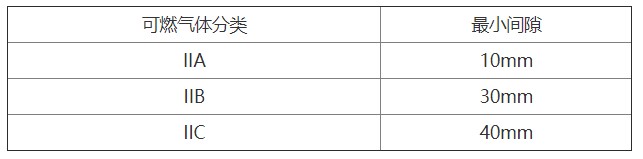

When installing equipment, attention should be paid to preventing the distance between the explosion-proof joint surface and solid obstacles (such as steel frames, walls, sheaths, installation plates, pipelines, or other electrical equipment) from not being less than the values specified in the table below, except for those that have been proven to have a smaller isolation distance.

1.15 When reassembling the explosion-proof casing, all mating surfaces should be completely cleaned and coated with appropriate grease to prevent corrosion and increase climate protection. The bolt should not be coated with lubricating grease if it does not penetrate through the hole. Only non-metallic scrapers and non corrosive cleaning liquids can be used to clean the flange. The radial clearance of the mouth, shaft, control lever, and threaded joint surface can generally be left unchecked, except for signs of wear, deformation, corrosion, or other damage. In this case, the manufacturer's documentation should be followed.

For inspection and maintenance purposes, the following new documents should be provided

a) Classification of hazardous areas;

b) Equipment level and temperature group;

c) Records that enable the maintained explosion-proof electrical equipment to comply with its explosion-proof type (such as equipment lists and equipment configurations, spare parts, technical data, and manufacturer's user manuals);

1.17 The entire device or equipment should undergo initial inspection before being put into operation. To ensure that the electrical equipment is in good condition and can be used in hazardous areas for a long time, one of the following two inspections should be carried out:

a) Regular inspections

b) Continuously supervised by professionals and maintained as necessary.

Specific inspection items can refer to relevant standards (see Appendix 1 and Appendix 2).

At any time, if there is a change in the classification of hazardous areas or a change in the location of electrical equipment, an inspection should be conducted to ensure that its explosion-proof type, equipment category, and temperature group are suitable for the changed conditions. If the device or equipment needs to be dismantled during inspection, measures should be taken to ensure that the overall explosion-proof type is not damaged during reassembly.

In areas where professional personnel have indicated changes in environmental conditions (such as solvent intrusion or increased vibration), explosion-proof equipment components affected by these changes should be inspected more frequently.

1.18 North American standard NPT threads cannot be connected to imperial threads, and corresponding reliable tightening and anti loosening measures should be taken when connecting NPT threads.

1.19 Cables and wires can be connected using one of the following two methods:

a) Indirect introduction, connected by a junction box or plug-in device.

b) Directly introduce, using the connection method inside the casing. Electrical equipment does not generate sparks, arcs, or hazardous temperatures during normal operation; The rated power shall not exceed 250w and the current shall not exceed 5A, and direct introduction method is allowed.

Regardless of the method of introduction used, measures should be taken to prevent damage to the wiring terminals when the cable is dragged or twisted.

When checking the tightness of cable entry devices in general, it can be done by hand without removing climate protection or protective covers. Avoid excessive force, as it may damage the internal wires. Detailed inspection can dismantle the cable entry device.

1.20 All wire and cable joints must be firmly pressed to avoid poor contact or short circuits. For example, when replacing a light bulb, the bulb contacts must be pressed against the lamp holder and not shaken.

1.21 Anti condensation devices, such as breathing elements, drainage elements, or heating elements, should be inspected to ensure correct operation.

When opening the equipment casing (devices other than intrinsically safe circuits) for inspection, attention should be paid to isolating the relevant connections (such as input, neutral, output, etc.), that is, unplugging the fuse and fuse, or disconnecting the isolator and switch, until there is enough time to reduce the surface temperature or stored electrical energy to not cause ignition before opening the casing.

During the use of 1.23 explosion-proof products, dust will continuously accumulate on the outer surface, affecting the heat dissipation of the shell. To ensure the normal operation of the product, the surface dust should be cleaned at least once a month. It should be noted that when wiping the surface of non-metallic materials, only a damp cloth should be used to avoid static electricity and ignition.

All parties involved in the design, production, inspection, use, and maintenance of explosion-proof electrical equipment must fulfill their respective responsibilities based on the requirements of "overall electrical explosion-proof". Attention to avoid: the main unit is explosion-proof, and the accessories are not explosion-proof; Equipment explosion-proof, instruments not explosion-proof; Part of similar equipment is explosion-proof, while the other part is not explosion-proof; Incomplete models of explosion-proof equipment, lack of matching spare parts, and construction problems.

Service hotline: 18924609560 (same WeChat account)